Right, so I've put together a first pass of the circuit (still needs a proper review so there are likely to be mistakes). The Pre-Amp is more or less a direct clone of the Quick Rod circuit, although I am tempted to tweak that clean channel a little more sparkly (possibly change the tone stack to something a little more Fendery).

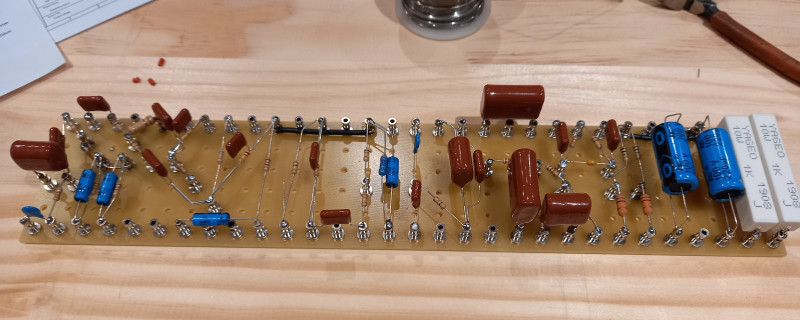

The Aux page has the circuitry for the footswitch controller (using optocouplers... more reading required) and the FET FX loop. Both of these will be built on veroboard, probably with the jacks mounted straight on the board, which will fix the board against the back panel of the chassis (now that I look at this, the FET option, may not save that much space over an extra valve... but it will be cheaper). My current design has duplicate buttons on the amp and the footswitch so that channel, gear, etc. can be controlled from either... I'm not 100% sure if this is going to stay however because those switches add quite a lot of real estate and I'm worried about the wires running backwards and forwards across the amp, although this would be minimised if they were mounted on the back, near the footswitch plugs...

The Output stage is a combination of the Quick Rod inverter and a relatively generic cathode biased EL34 circuit (although, actual value of bias resistors may change). It also has a Post Phase Inverter Master Volume thrown in for good measure.

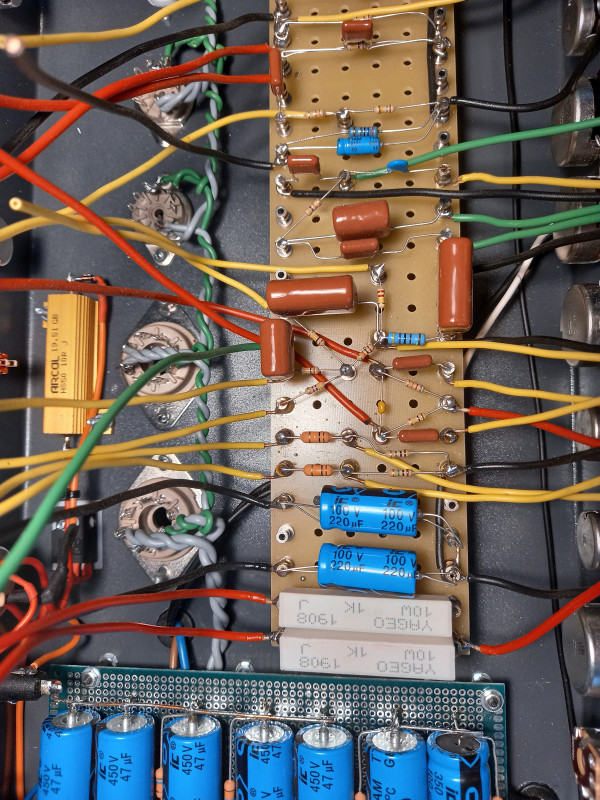

Power supply is relatively generic except for the added Power Scaling, I've included the chip number that I used for my 15W black face clone, if I remember correctly it should be able to handle the current but I will need to double check, current plan is to mount this directly onto the chassis for heat conducting. I'm aiming for the voltages specified on the QR schematic and may need to teak a few resistor values to get them but in my (limited) experience these aren't that critical for the pre-amp tubes, provided your power amps have the correct voltage. I've also included some pretty beefy capacitors and an over-sized power transformer. The reason for this is that I want a properly stiff power supply for this amp to prevent it from loading down. Incidentally, I've gone with a half wave rectifier simply because of the transformer I've found, if we get one wound, I'll probably look at halving the voltage and going bridge rectifier.

Next it's on to the layout, which will help us size the chassis and ultimately the head itself... this is quite a complex beast, so I expect it to be large.

p.s. on a side note, everything I know about grounding I learnt from the Valve Wizard. (http://www.valvewizard.co.uk/Grounding.html) For this amp, I'm planning on using the star grounding layout with chassis connections only at the AC plug and the input jack. Heater wires will be earthed via center tap on the transformer.