OK, waaaay off topic I know but I don't have any other friends so I thought I'd turn to my friends here at GFSA ?

I recently bought a wall mounting bracket for our TV. It has a metal plate to which the TV is fixed but the problem is that it interferes with the cables on the back of the TV set. If I could cut away a section of it everything would work fine but I don't have the tools to cut through 2.5mm sheet metal (I don't know what type of metal this is but it seems tough). I'm sure I could use an iron saw but I'm pretty sure the results won't be very neat.

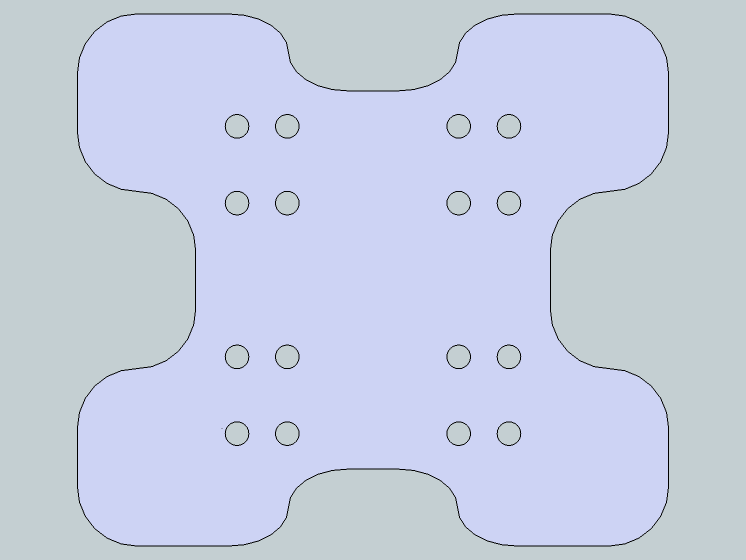

So I was wondering if any of yous might know where I could take this to have it altered for me. Basically, this is what it looks like now:

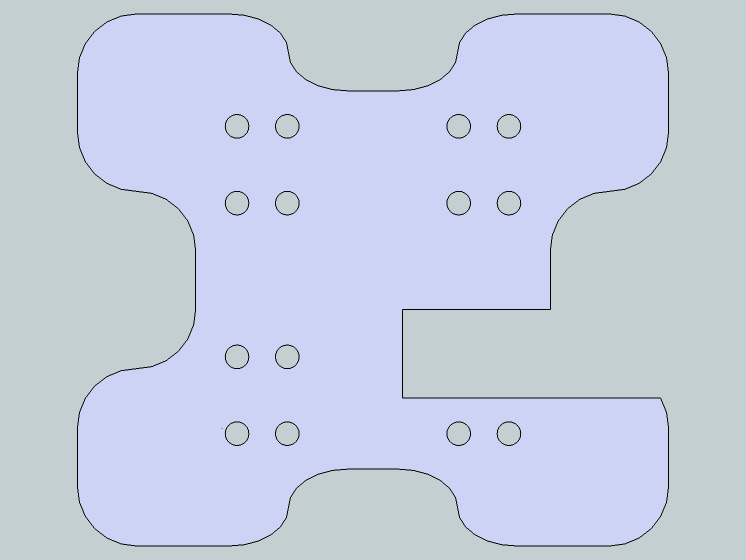

And this is what I want it to look like:

Don't worry about the structural integrity, there will be plenty of metal left to offer the rigidity that is needed.

Any ideas, anyone?

I recently bought a wall mounting bracket for our TV. It has a metal plate to which the TV is fixed but the problem is that it interferes with the cables on the back of the TV set. If I could cut away a section of it everything would work fine but I don't have the tools to cut through 2.5mm sheet metal (I don't know what type of metal this is but it seems tough). I'm sure I could use an iron saw but I'm pretty sure the results won't be very neat.

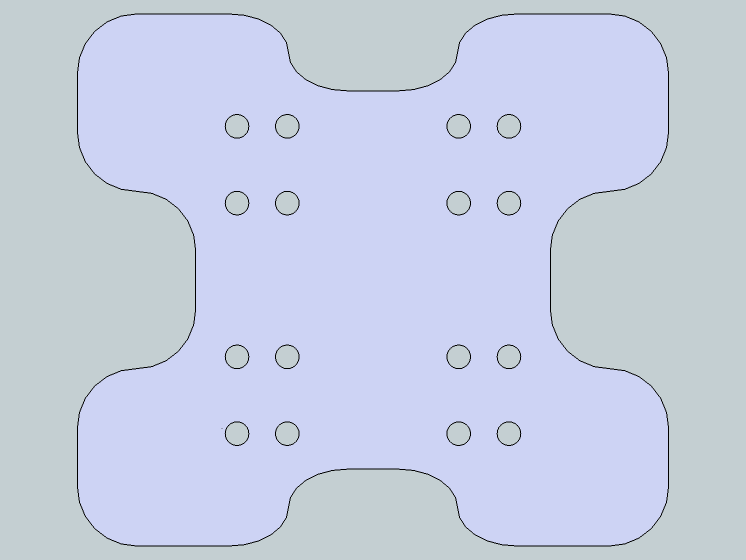

So I was wondering if any of yous might know where I could take this to have it altered for me. Basically, this is what it looks like now:

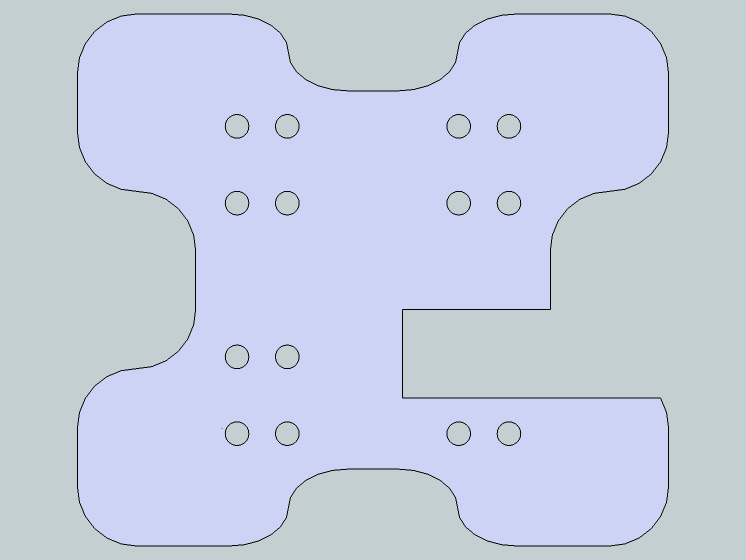

And this is what I want it to look like:

Don't worry about the structural integrity, there will be plenty of metal left to offer the rigidity that is needed.

Any ideas, anyone?