Aha, I finally made some progress again. I didn't get binding, but I phoned a guy who put me through to a guy, to put met through to another guy etc.. Basically, someone suggested I try what is called edging. Turns out it's exactly the same stuff as the stewmac binding, only difference is it's not pre-cut. So got 2 rolls of 2mm and 3mm each 2m long. Firstly, how would I best go about getting this down to a width of 6.35 mm? I tried a small piece, which I marked with a ruler and then cut with a dremel disc (see pic) but there has to be a better way to do this for 2m. Also, how on earth will I cut a 3mm channel for the binding? I know there is a stew-mac bit with the appropriate bearing, but I really don't want to order a single router bit from them at cost for a one-off project.

What I did in the picture above, is I used a straight piece of mdf and moved it 3mm away, but this won't work for the body unfortunately. Here is another pic:

I'm also curious as to opinions on the order of doing things here. Should I install the binding, then finish the body, then scrape it off? Because I tried that approach, but ended up sort of damaging the spray-paint image. Or should I rather mask it off, or else just finish first, and then glue binding. Last option doesn't really make sense to me though.

The binding for the neck isn't a problem, because I have the template which I could just offset by 2mm.

I'm also not entirely sure how to do the fretboard. As far as I know, there is a piece of fretboard sticking out beyond the nut, but no idea how much. Then again curious about order of things, I'm guessing I should first slot the fretboard, then bind or radius, then fret. Thanks Gearhead, I sent you a pm.

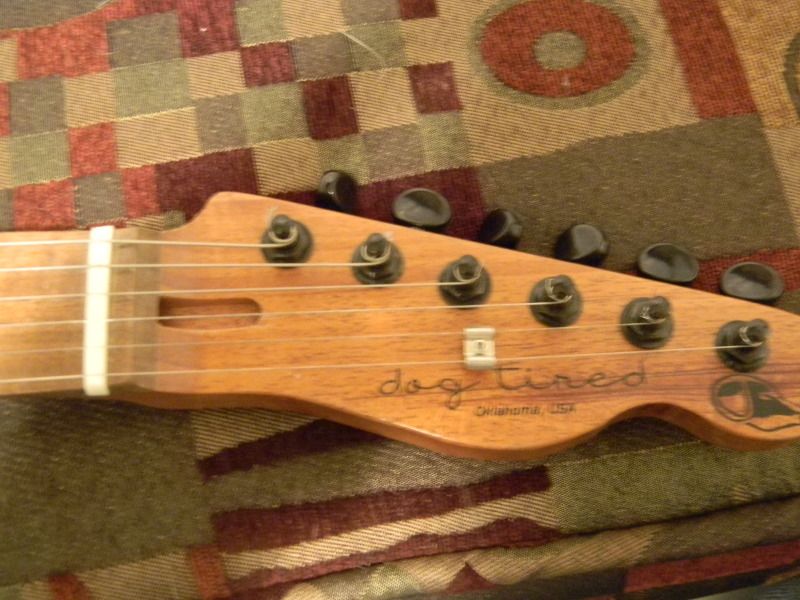

Here is another pic of some of the parts. Thanks Average Joe!!

I have decided, best bet would be to install the truss-rod with heel-adjust. The guys at the fretshop also said, that if the truss rod is installed properly, and set up right, fiddling with is won't be necessary that often.

Here is also a pic of the belly contour, I sort of just winged this part and still have a bit to do.