Wizard wrote:

Insight: pickup position is one of the very few things that can't be tweaked with a screwdriver or allen key after the build is finished

Sent from my SM-G920F using Tapatalk

good point.

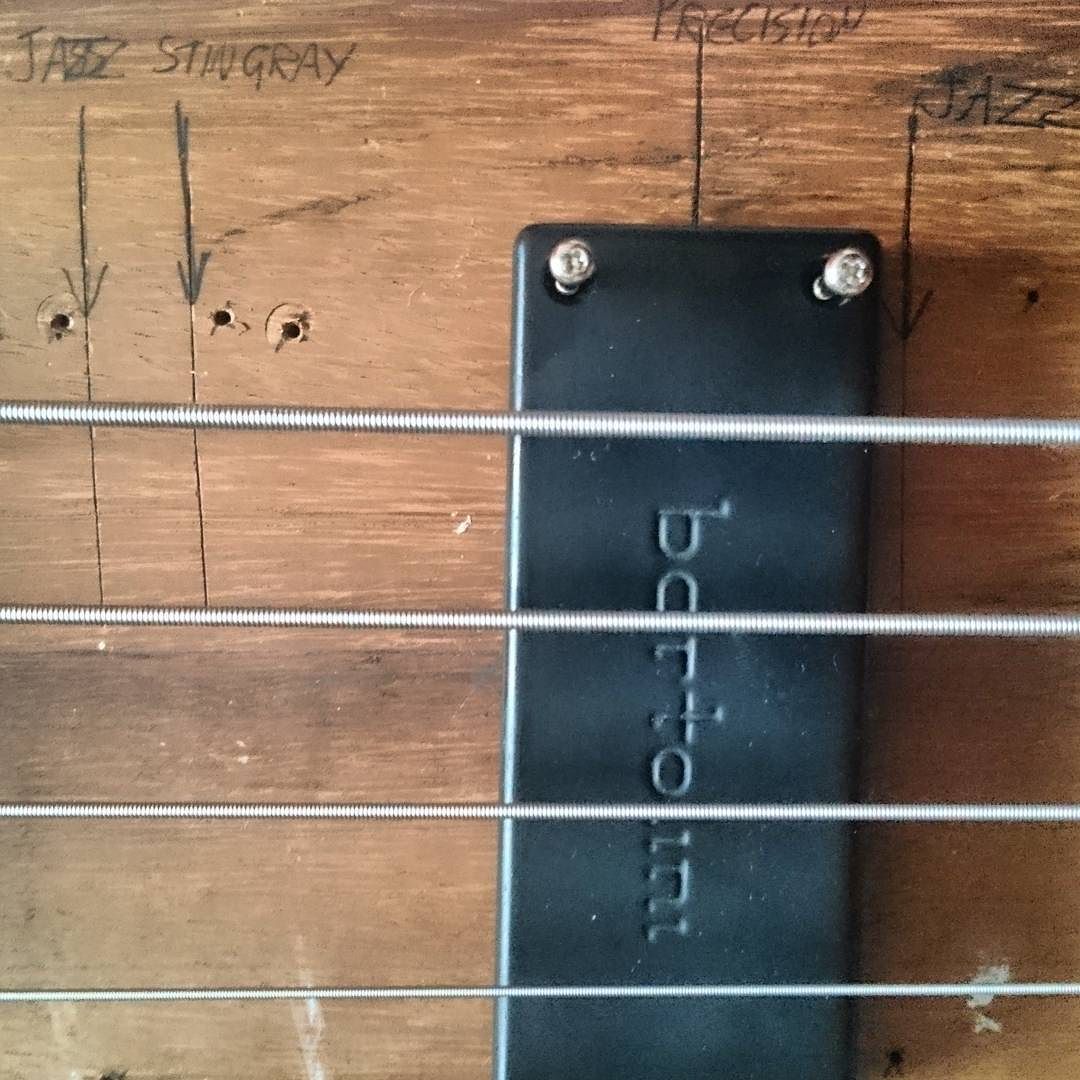

Here is a pic of some of the positions on the test rig:

At the end of the day, towards neck- boomier, towards bridge- thinner, and it's more or less personal preference beyond that. I found that going closer to the neck than the P bass position started losing definition, and passively the stingray position was too thin. With the preamp however, I was able to dial a bit of thump in, so I'll be placing the pickup centred at the Stingray position, which is pretty close to where it was on the Cort Curbow this came out of:

I've just picked up a piece of Oregon Pine at

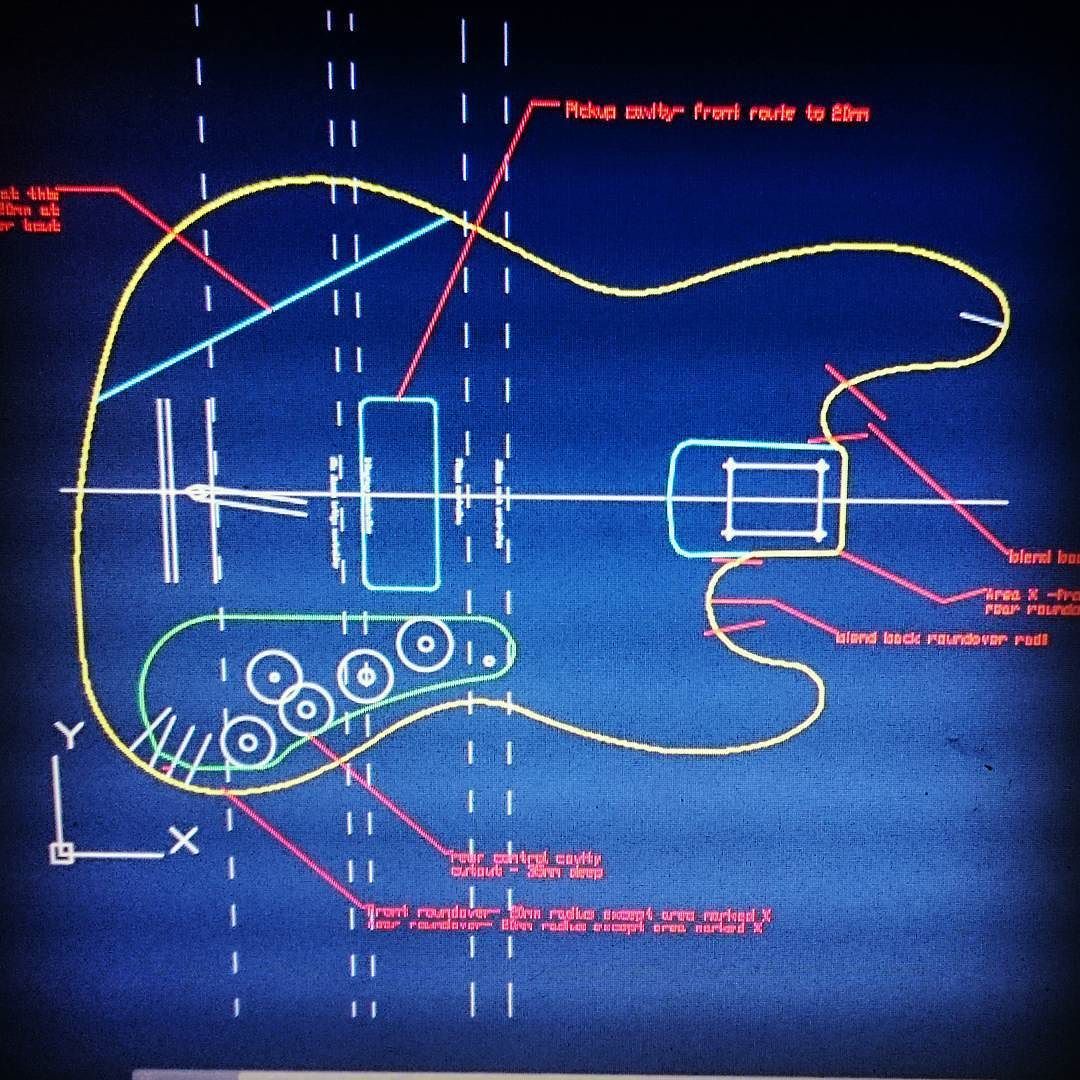

Country Woods, so I hope to be routing the body in the next few weeks.