Alrighty, time for some more progress on this project. We pick up the story where the side plywood planks have been scored and ready to be bent around the template.

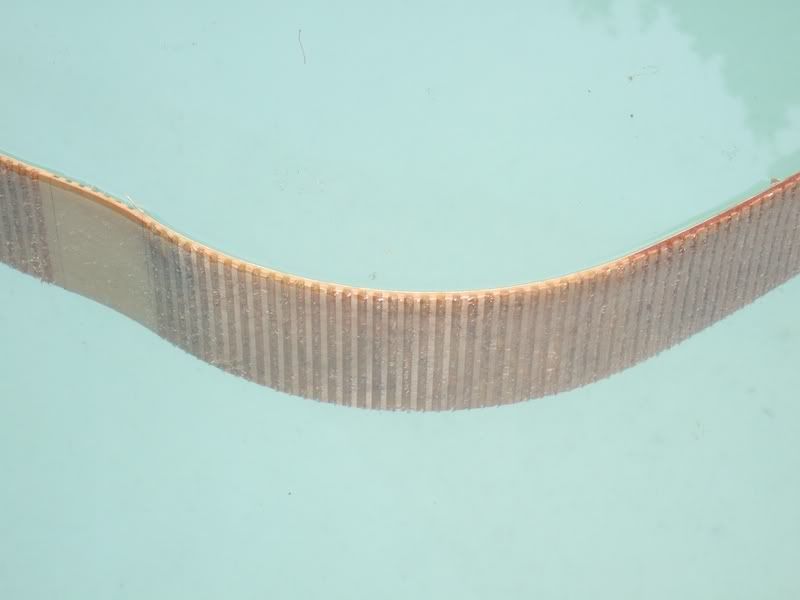

I started by chucking the scored plywood in the swimming pool where I let it soak for 2 hours. The plywood started forming a nice curve along the scored sections. I didn't expect this but I figured it was good as it would make shaping it around the template that much easier. However, the warping took place in the opposite direction as the direction in which I had intended bending it. Notice how the scoring is on the outside of the bend.

And once I took it out of the water, this is what it looked like

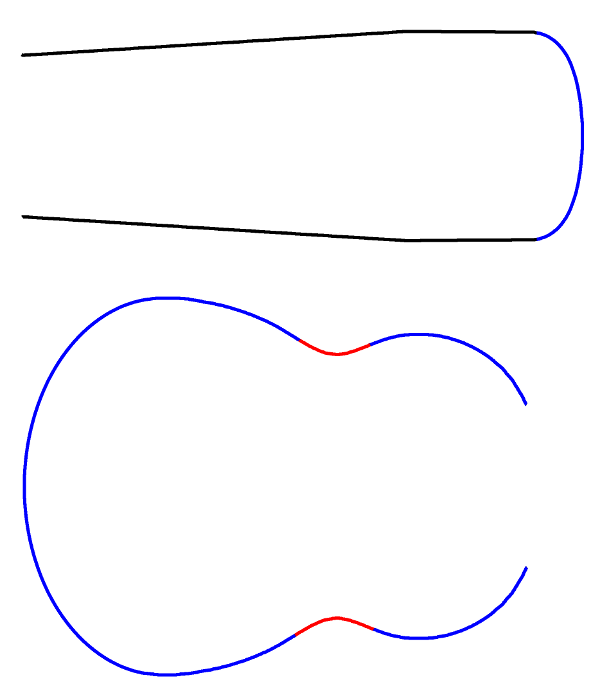

I don't have pictures of it but I bent the neck section around the template, bending it against the newly assumed curve, and it worked perfectly. I figured I'd do the same with the body section because I did want the scoring on the inside of the case. This was a mistake and I realised it as soon as I heard a crack in the plywood when I started tightening down the clamps. I released the pressure immediately and shaped the plywood back to it's assumed curve. Sorry, I missed taking a few pictures but here is a picture of the bending with the scoring on the outside.

This would have worked, but alas, the damage was done and the crack was just too severe. I had to accept the dreaded truth that I was going to have to score a new plank for the body section.

The problematic area, as expected, was the red section in this picture:

So I decided I'd score the entire plank on the same side this time. It would mean that the plywood would still be bent against its assumed curve for the blue sections but on the problematic red section it would be bent along with its assumed curve.

This is what it looked like after coming out of the swimming pool

So I bent it around the template and clamped it down. This time, no cracks, it worked like a charm.

As you can see in this picture, the plywood shaped beautifully around the red section

I left that standing overnight so that the plywood can dry and set in the new shape. Next came gluing it to the 9mm supawood base, using this stuff:

This binary epoxy, on NeonGecko's recommendation, worked perfectly. It's a tad more expensive than some other epoxies but I am amazed at how strong this stuff is.

So I applied the epoxy mixture to the sides of the template, laid it down flat on the working surface, put one of the inner templates on top of it and got ready to add the bent plywood and clamp it down with the outer template. I should have noticed at this point, but didn't, that there was going to be epoxy overflow and I'd be gluing the template to the base as well :?

So I continued to clamp it all down and left it overnight again. Note that in this picture, the epoxy is only applied to the bottom plank. The top template is only in place to keep the case as true to it's intended shape while the epoxy is setting.

Like I said, I am amazed at the effectiveness of this Epidermix epoxy and, considering the small amount of epoxy overflow, it took some aggressive wedging to pry the template loose from the base.

I repeated the process for the neck section, this time not putting the inner template directly on top of the base and after another night, this is what I got

Things are starting to take on shape nicely. Using a plastic spoon, I applied a gusset of epoxy to the body section. I'll do the same for the neck section but haven't gotten around to doing that yet.

Have I mentioned that this Epidermix is impressive stuff!

So at this point I need some advice again. As you can see on the second to last image, the plywood for the neck section and body section will now need to be fixed together somehow. When I cut a new plank for the body section having cracked the first, I got my measurements wrong so now there's something like a 4mm or so gap between the body and neck sections. Also, the plywood strips are not standing up at exactly 90 degrees from the base. The neck section is leaning in somewhat while the body section is leaning out. I'm not sure exactly why this is because I clamped the strips down with the templates both at the bottom and the top while the epoxy was setting but I think it is related to the fact that the plywood is not entirely rigid and loses some of its curvature towards the top where it is not supported by a supawood plank.

I'm currently considering the following three options. Would appreciate your thoughts on them or if you have any better suggestions.

1. Simply taping the two together with duct tape. Originally I liked this idea but I'm moving away from it now. If the pieces where flush already it might have worked but considering that there is a 4mm gap now and that the plywood is not at a right angle to the base I don't think duct tape will offer the neccessary strength to keep the plywood in shape. It will simply hold it together and fill the gap.

2. Gluing a strip of paper (or maybe rather thin plastic) on the outside of the join and on the inside of the join with this Epidermix and using enough of it to fill the gap between the strips of ply. Then Clamping the box to the templates again while the epoxy is setting.

3. Finding some sort of thin angle iron (maybe aluminium) that can be bent open somewhat (the join is not exactly 90 degrees, more like 110 degrees), putting it on the inside of the join and riveting the plywood to that.

I'm leaning towards number 2.

Also, while the plywood shaped nicely around the base, it still loses some of its curvature towards the top (open part) of the case. I knew this was going to be a concern and I was hoping that I'd stumble on inspiration during the course of the project but so far I haven't. The best idea I've had so far would be to find a strip of aluminium that's around 3mm thick and 10 to 20mm wide, bend this strip around the template and use it as a stiffener on the top edge and inside of the case. It's important that I find some sort of a sollution to this problem as there will be no way to make a lid that fits nicely over the case if the top end of the case does not conform to the same shape as the bottom end.

So, the floor is open. Fire away with your brilliant suggestions pelase. ?