teleplayer

Hey Guys,

For the first time ever, I managed to break an A string. I was rather surprised, but didn't think much of it. I changed it out and continued with practice as usual. When I came to play yesterday, I opened my case and found that without me even playing, the A had broken again. >☹

Luckily a friend had another guitar for me to use, but I need to sort this problem out. I can't get to a gig and find a broken string like this all the time.

I do always carry a spare set, but with this frequency I may need 6 A strings sitting in my case.

Any suggestions?

It's a '96 strat with the modern saddles.

arjunmenon

I'm not a boffin but have you checked the saddle for any burrs or sharp edges?

You could try using a high grit abrasive cord to smooth out the area of the saddle that the string travels over.

teleplayer

I tried to look for any sharp edges, but perhaps my untrained eye isn't picking any up.. I don't have any abrasive chord, but maybe it's something that could be sorted in 2 mins by a music shop? I don't want to screw anything up, especially since it's a limited edition and I'd rather not have to change out any parts due to my self fix attempt.

Psean

I had problems with the A string on my Strat breaking - and it's a 42 gauge. I found that the A saddle had a groove that had worn into it and had become burred in the edge and was causing the breakages.

EDIT: Beaten to it ?

singemonkey

Arjun Menon wrote:

I'm not a boffin but have you checked the saddle for any burrs or sharp edges?

You could try using a high grit abrasive cord to smooth out the area of the saddle that the string travels over.

Where would one find such a thing?

AlanRatcliffe

I agree with the others, it does sound like a burr on the saddle. With the downward pressure it doesn't take much. Wrap some 600grit waterpaper 'round something thin like a key file or small hex (allan) key and work it through the slot a few times. Also with a cast block saddle, check the rear of the saddle hole where the string goes down to the plate and block.

Also check where the string leaves the top plate on the bridge, below the saddle. With some intonation settings (usually more an issue on the unwound strings than the wound) the string can contact the edge there and wear through quickly. SRV's tech used to use thin plastic sleeving over the string at this point, but I don't find that necessary - I just round off the edges of the holes.

DaFiz

A recurring problem. Easier to replace the set and keep the old ones as spares in case it happens again.

Sometimes they're hard chrome plating over other softer alloy beneath and sanding shows.

studmissile

Also what strings re you using, I remember having a similar problem with Elixers a while back. I bought a couple of nano web packs, but them on within a few minutes the g string breaks, replaced and same string and breaks again. Put it down to a dodgy batch. Tried EXP's and never looked at Elixers again.

teleplayer

I was using Elixers, I've just put a set of Fender strings on now (freebies) so I'll see how those do. When I change again, or get a break, I'll try sanding down the saddle. I have gold hardware, so getting replacements would be a bit more of a mission, so i'd like to avoid it if possible.

studmissile

Yeah!, check the string batch serials, if they close it could be the actual A string ( I remember reading about dodgy string and how in the USA Elixer was calcining strings with 2 free packs if you handed your old ones in) , if you want nano webs (or longer life strings) try D'Addarrio EXP's

Terribly frustrating!

teleplayer

I've been doing some reading up and Fender suggests applying 3in1 machine oil to the saddles for lubrication each time you change strings. Just need to find some and give it a try. I used to apply it to my Tele, but that was when there was some lying around in my Dad's workshop, I need source some now.

AlanRatcliffe

Oil isn't the solution, regardless of what Fender says. A sharp edge is a sharp edge and lubricant only reduces friction, it doesn't remove it.

Non drying oils also should be used with extreme care on guitars as they have penetrating properties and are incredibly difficult to remove. They soften and expand woods and get in the way of any finishing or glueing, causing problems with lifting finishes and any future repair work. They also attract and hold dirt and fluff, resulting in a sticky mess..

If you must use a lubricant, get a dry one like Teflon or graphite. Still, the best solution is to remove and smooth any sharp edges.

teleplayer

Thanks Alan,

Appreciate the advice! Will take it in to get looked at when I get a chance. Any suggestions for places around JHB? I know Music Connection have an exceptionally long line of guitars waiting for repair and setup.

Arno-West

As a last resort, replace all the saddles with Graphtech saddles. Keep the old ones if you want to sell the guit one day. I replaced the saddles on my '73 Strat 15 years ago with the Graphtechs and haven't had even 1 broken string since then.

slyd

Arno West wrote:

As a last resort, replace all the saddles with Graphtech saddles. Keep the old ones if you want to sell the guit one day. I replaced the saddles on my '73 Strat 15 years ago with the Graphtechs and haven't had even 1 broken string since then.

+1

Alternatively . . .

I was brought an Ibbo RG series axe (metal machine), which kept breaking the low E, and A string.

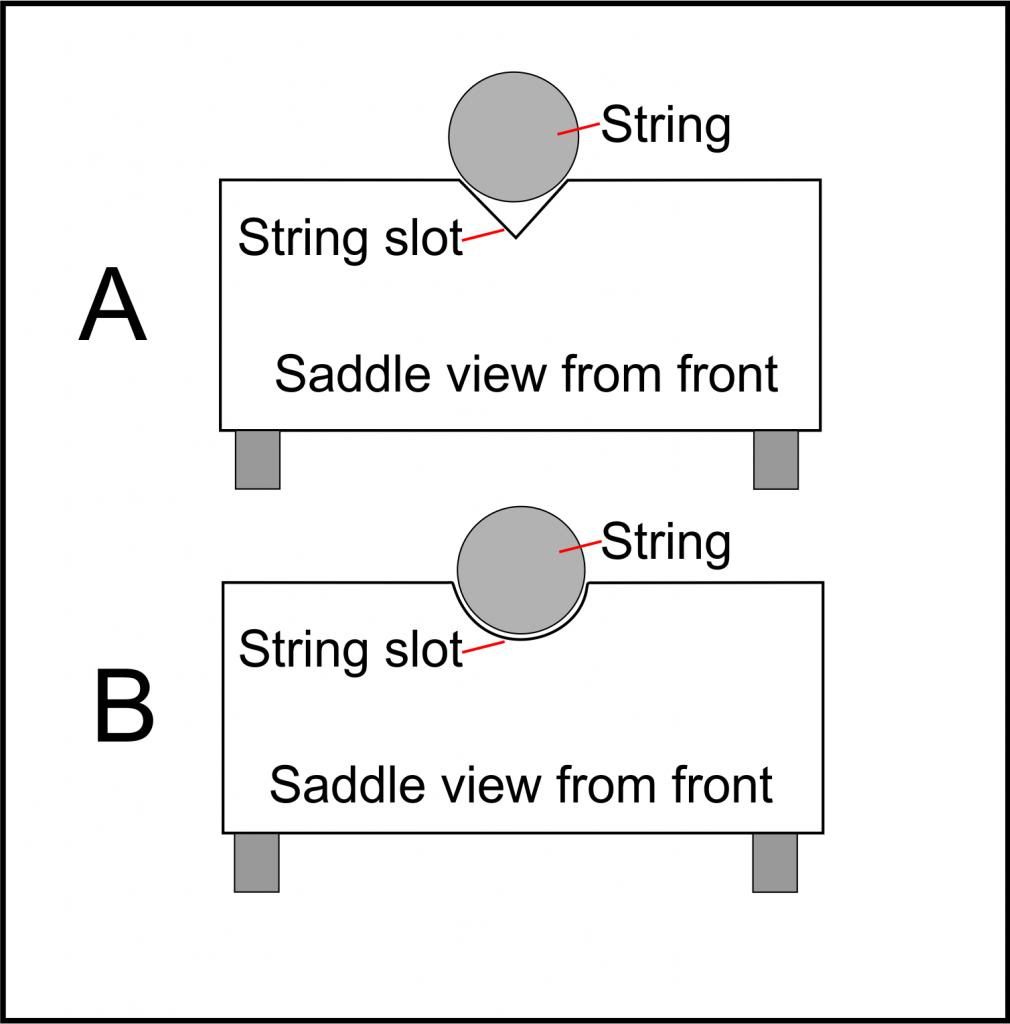

Close inspection revealed that the E & A strings, did not sit snug in their respective saddle slots (See pic A).

As mentioned, a bit of filing and gentle sanding, shaped the slot so that the string could slide smoothly, without any sharp points of contact (see pic B)

This solved the problem completely = happy customer ?

Psean

Alan Ratcliffe wrote:

Also check where the string leaves the top plate on the bridge, below the saddle. With some intonation settings (usually more an issue on the unwound strings than the wound) the string can contact the edge there and wear through quickly. SRV's tech used to use thin plastic sleeving over the string at this point, but I don't find that necessary - I just round off the edges of the holes.

Necroposting, I know...

Would there be any downsides to using plastic sleeves?

I was having major string breakage problems (busting 42 and 52 gauge strings at the saddle regularly) and de-burred the saddles and rounded off the edges of the holes. It's helped for the most part, but I just broke another A at the saddle. I at least managed to get the set to where they were due for replacement anyway but still, I only ever break the thickest two strings. So I'm having another go at rounding the edges of the hole, but was wondering whether the plastic sleeves might be worth a shot.

Psean

Actually, after taking the broken end of the string out and having a closer look it seems that it broke at the saddle and not the hole. S'pose I save towards some Graphtechs then...